China Word Connection CO.Ltd

You tech promotional products supplier in China

Introdcution

Factory was built in 2006, mainly produce usb flash drives, usb charging cables, power banks, Bluetooth Speaker, wireless chargers, employees 60 experienced full time workers, 15 for Charging cables production, 15 people making housing, rest 30 with assembly. Capacity 3k/day for charging cables, 2k/day for PVC housing , 8k for assembly.

PVC Mold development

The PVC casing is made by injection molding, and the middle part needs to be glued-high temperature baking-cooling. To meet extra production needs during high peak season, we have equipped a precise automatic dispenser. The following is the specific process of PVC:

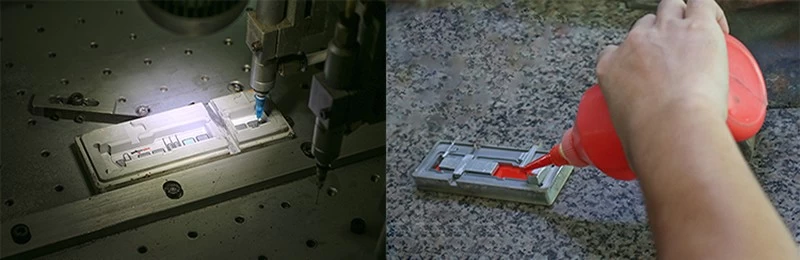

Creating the mold:

When clients confirmed the artwork, we will have worker set the program for the mould. The pouring system of the PVC mold will be processed according to the programmed program. The simple mold takes several hours to produce, and for complicated mold it could take one day.

Dispensing:

Manual dispensing, after toning the raw material, workers would manually pour the paint to the mold, they have the experiences to pour the right amount, there are 6 workers who all has 5 plus years at the production line.

Automatic Dispenser:during the fixed time, the machine would inject the material to the mould, the material volume was controlled by fixing the processing time, Automatic dispenser process 200pcs a day.

Baking - PVC shell

After dispensing, it will be sent to a baking space for a solid state, the temperature of baking space reaches 180-200 °C.

Refrigeration -

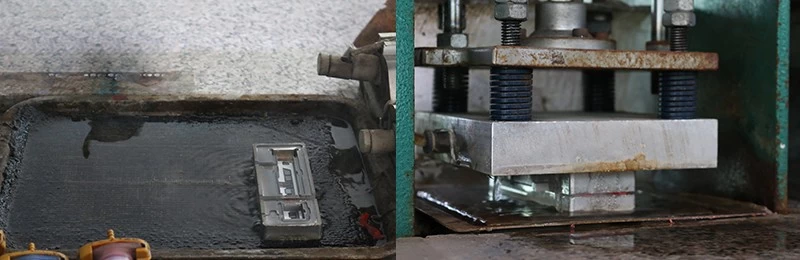

After baking, it will be put in a water pot for cooling until next procedure. When cooling, the mold temperature will be in 30 °C -60 °C.

Sharpening - Trimming

After cooling, there will be some extra trimmings that caused by heating, our workers would shave them off from the housing.

Cable Production

Making cable body

According to the order request, our sub supplier making the raw cable from Polyester, TPE, leather, PVC etc.First we will wrap the cooper wire with materials like TPE, then put the TPE cable into the water sink to cool it down, then roll up into a circle. The machine needs to be running for 30mins for the right temperature before it start working. And it will have loss in a percentage, so we request 5000pcs MOQ for a customised material.

Cutting the cable

We cut the cable to the proper length according to order request, our standard all in one cable are 15cm long, lanyard charging cable are 85mm long.

Welding

After cutting the cable to the right length, we move to welding, before that, workers will peel off a a short length of housing, that leaves the cooper wire operable for welding, one side will be soldered with a connector like USB 2.0, all tin paper are environmental friendly.

Welding checking

We will do checking for all semi-finished cables to avoid empty soldering

Ultrasound closing

After welding, we will use ultrasound equipment to fix the cap, the cap is used to rap around all the cables inside, so now you will see an all in one cable with different colors and connectors.

Imprinted Logo

All artwork files will be forwarded to production line, worker will use the printing file to create logo pattern, then toning the paint and print the logo cap through printing machine, all printed caps will be sent back to production step 5. All printing are done with semi-finished parts like caps, it’s small and easy to control.

Final inspection

After production finished, we need to full test the products, includes function test and appearance test, function test are: if the connectors working properly, if the power of the connectors stable, appearance inspection: if any paint has been scratched, if the logo right color and size

Packaging and shipment

After products passed inspection, the shipping line will start packing and get ready for pickup.

Our Factory address

zone B,5 building,mei'jia'mei industrial park, guiyue road, guanlan street,longhua,shenzhen.